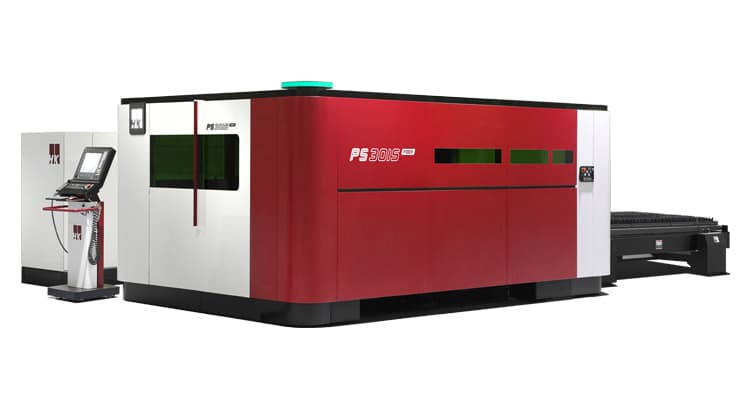

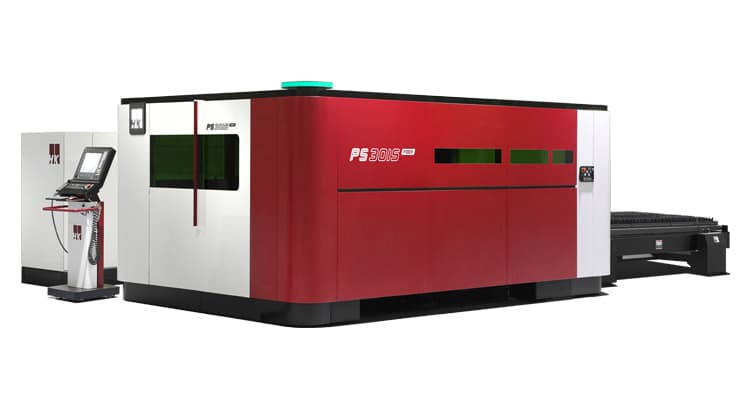

Fiber Laser Cutting Machine Table

A large-sized fiber laser that brings fine, high-precision processing to projects of nearly any size.

It has a motorized entrance. It is compatible with FSL Muse Pandora on a desktop.

Other options include 6.9"x6.9", 5.9�x5.9�, 4.3�x4.3�, 2.6�x2.6� and 2.6�x2.6�. They can be chosen depending on the operational need.

When using fiber laser machines to cut projects, it is necessary to learn the use and maintenance skills, in order to better exert the effectiveness of the equipment and maximize the efficiency of the equipment. 1. Check the steel belt frequently to ensure the tension. Otherwise, if something goes wrong during operation, people may be injured and serious death may result. The steel belt looks like a small thing, but the problem is still a bit serious. 2. Check the straightness of the track and the verticality of the machine every six months, and find that it is abnormal and timely maintenance and debugging. Without this, the effect of cutting may not be very good, the error will increase, affecting the cutting quality. This is the top priority and must be done. 3. Use a vacuum cleaner to suck off the dust and dirt in the machine once a week. All electrical cabinets should be closed and dustproof. 4. The guide rails should be cleaned frequently to remove dust and other debris, to ensure that the equipment racks are cleaned frequently, and lubricating oil is added to ensure lubrication without debris. The guide rail should be cleaned and lubricated frequently, and the motor should also be cleaned and lubricated frequently, the machine can move better during cutting, cut more accurately, and the quality of the cut product will improve. 5. If any damage is found in the process of using the machine, it must be replaced in time, which is not only a type of protection for the machine itself, but also ensures that the machine always maintains an ideal cutting effect.

So, if your metal cuts need to be precise, then you need a laser cutter. If you just need to cut simple shapes, and thick ones, then a plasma laser should be alright.

Raycus laser, a popular laser source brand, is used by many laser cutters and engraver companies. Raycus is often mentioned in the catalogs for different laser manufacturers. This means that all these machines are equipped with a Raycus Fiber Laser Technologies Co. Ltd. Laser source.

A large-sized fiber laser that brings fine, high-precision processing to projects of nearly any size.

It has a motorized entrance. It is compatible with FSL Muse Pandora on a desktop.

A special type of fiber laser known as MOPA fiber laser, provides greater control over pulse width and frequency parameters to produce color laser engravings on metals.

Raycus 50W Fiber Laser can be used to etch and mark aluminum at 90 degrees angles. It uses 100% of the laser's power.

A fiber laser has eliminated the need to align beam paths and mirrors with optical fibers.

Fiber lasers can be used in laser engraving and laser marking machines. A fiber laser is able to laser cut sheet metal, which is the main difference between it and a CO2 laser.

Just know that the running cost of plasma is lower than laser. In general, it cost about 15/hr to run plasma cutting machines. It takes about 20/hr to run a laser machine.

MCWlaser Pro is intended to be used on metals such as steel or stainless steel, silver or copper, alloy, aluminium, etc.

They can import different file formats including DXF, BMP, DXF or AI.

The laser source is at the heart of any fiber laser. A fiber laser does not use any gaseous medium like a CO2 one.

In fact, the diode module in a fiber laser typically outlasts other technologies by three times. Most lasers have a lifespan of about 30,000 hours, which equates to about 15 years of use. Fiber lasers have an expected life of 100,000 hours, which equates to 45 years of use.

Maximum material cutting thicknesses by 1000W fiber laser cutting machine: Carbon steel has a maximum thickness of 10mm; stainless steel has a maximum thickness of 5mm; aluminum plate has a maximum thickness of 3mm; and copper plate has a maximum thickness of 3mm.

Compressed air, nitrogen, oxygen, and argon are the four primary types of assist gas for fiber laser machines.